Conveyor rollers are essential components of mine conveyor systems, playing a critical role in supporting the conveyor belt and material weight while reducing operational resistance. High-quality rollers not only enhance conveying efficiency but also extend the lifespan of conveyor equipment. This article provides a comprehensive introduction to the structure, types, performance advantages, and application areas of mine conveyor rollers.

1. Structural Features of Mine Conveyor Rollers

- Roller Shell

- Made of high-quality steel pipes or special plastic, with a precision-machined surface to ensure excellent roundness and concentricity, minimizing belt wear.

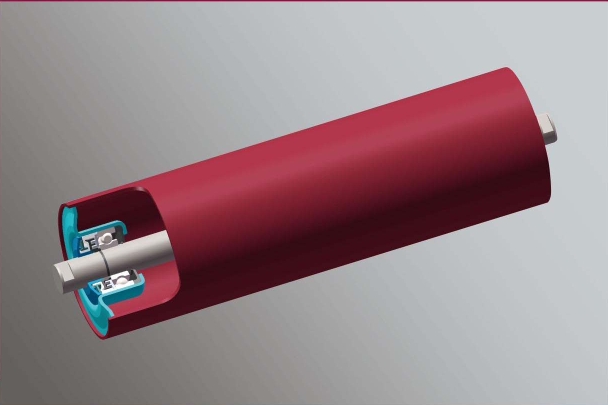

- Bearing Housing

- Manufactured from high-precision steel materials, ensuring stability and reliability under heavy loads.

- Sealing Device

- Multi-stage labyrinth seals effectively prevent dust and moisture ingress, ensuring smooth operation and extended service life.

- Bearings

- Equipped with high-quality, heat-resistant, and wear-resistant bearings, enabling continuous long-term operation.

2. Types of Mine Conveyor Rollers

Based on usage and structure, mine rollers can be categorized as follows:

- Trough Rollers

- Support the conveyor belt and materials, suitable for transporting bulk materials.

- Parallel Rollers

- Support the return section of the conveyor belt, preventing belt sagging.

- Self-Aligning Rollers

- Automatically correct belt misalignment, ensuring stable operation.

- Impact Rollers

- Installed at loading points to reduce the impact of materials falling onto the belt.

- Anti-Stick Rollers

- Specially designed to prevent material adhesion, ideal for handling wet or sticky materials.

3. Performance Advantages of Mine Conveyor Rollers

- High Load Capacity

- Made with high-strength materials, capable of handling heavy loads and harsh working conditions.

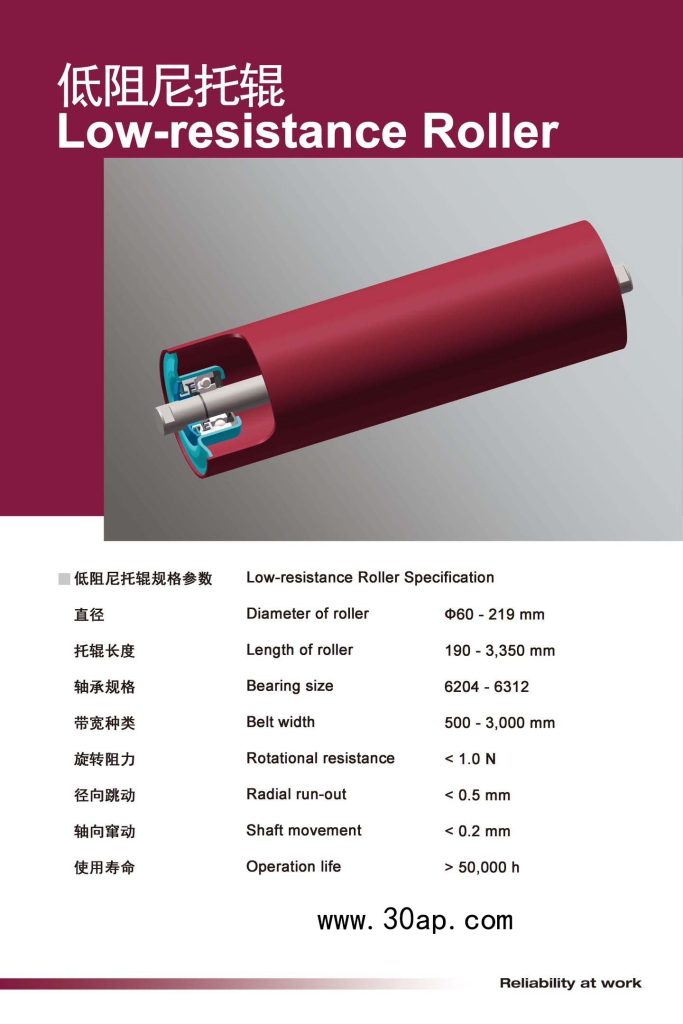

- Low Rotational Resistance

- Precision machining and high-quality bearings ensure smooth operation and reduced energy consumption.

- Strong Corrosion Resistance

- Surfaces are treated with galvanization, coating, or rubber covering to withstand humid and corrosive environments in mines.

- Long Service Life

- Exceptional sealing performance effectively prevents dust and impurities from entering, reducing failure rates and maintenance costs.

- Easy Maintenance

- Designed for easy installation and replacement, minimizing downtime.

4. Application Areas of Mine Conveyor Rollers

Mine conveyor rollers are widely used in various mining, coal mining, and industrial conveyor systems, including:

- Open-Pit and Underground Mines

- Transporting bulk materials such as ore and coal.

- Metallurgical Industry

- Supporting conveyor systems for slag and coke in steel plants.

- Power Industry

- Conveying coal and ash in thermal power plants.

- Ports and Terminals

- Used in bulk cargo loading and unloading systems.

5. Selection Recommendations for Mine Conveyor Rollers

- Select the appropriate roller diameter and length based on conveyor belt width and material weight.

- Choose anti-corrosion, waterproof, or anti-adhesion designs according to the operating environment (humidity, temperature, corrosion, etc.).

- For energy efficiency, select low-resistance rollers to reduce power consumption.

6. Conclusion

As an indispensable component of conveyor systems, mine conveyor rollers directly influence the overall efficiency and operating costs of the equipment. By selecting suitable roller models and ensuring regular maintenance, the stability and economic benefits of mining conveyor systems can be significantly improved. If you require assistance with roller selection or customization, feel free to contact our technical team for professional solutions!