In the installation process of conveyor belts, avoiding belt twisting is a key step to ensure its normal operation and extend its service life. Once the conveyor belt twists, it will not only affect the normal transportation of materials but may also lead to premature wear, tearing of the belt, or even cause equipment failures, resulting in production stoppages. Therefore, mastering the correct installation method and effectively preventing belt twisting is crucial.

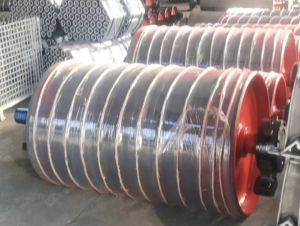

Preparation before installation is the foundation for avoiding conveyor belt twisting. First, a comprehensive inspection of all parts of the conveyor system is necessary to ensure that components like rollers and idlers are securely installed and in the correct position. The axes of the rollers should remain parallel, and the idlers should be arranged neatly and rotate freely. Any deviation in the installation of rollers or idlers can cause uneven force on the conveyor belt during operation, leading to twisting. For example, if the roller is installed at an angle, it will result in uneven force on one side of the conveyor belt, causing it to gradually shift towards the side with greater force and twist. Therefore, professional measuring tools such as a level or theodolite should be used before installation to check and adjust the accuracy of roller and idler installation to ensure they meet the design requirements.

At the same time, the conveyor belt itself should be carefully inspected. Check whether there is any damage, deformation, or unevenness on the belt surface, especially along the edges. If the conveyor belt is damaged during transportation or storage, or if the edges are uneven, it is prone to twisting during operation due to uneven force. For example, if the edge of the belt is partially damaged, the difference in force between the damaged and intact parts will cause the belt to shift towards one side, resulting in twisting. Conveyor belts with such issues should be repaired or replaced promptly.

During installation, the correct unrolling method is an important step in preventing belt twisting. Conveyor belts are usually packaged in rolls, and when unrolling, a spacious, flat area should be selected to avoid unrolling on narrow or uneven ground. During the unrolling process, ensure the conveyor belt unrolls smoothly without jumping or getting stuck. Special unrolling equipment, such as an unrolling stand, can be used to place the conveyor belt roll on the stand, adjusting its height and angle to allow the belt to unroll smoothly. Additionally, assign a person to guide the conveyor belt during the unrolling process to ensure it unrolls along the intended direction, preventing it from coiling or twisting.

When installing the conveyor belt, make sure it is in the correct position on the rollers and idlers. The belt should be evenly laid on the rollers and idlers, avoiding any bias to one side. When placing the belt onto the rollers, start from the center of the roller and gradually unroll it towards both sides, ensuring that the belt makes full contact with the roller surface and fits tightly. For multi-roller conveyors, attention should be given to the coordination between rollers to ensure that the belt’s position is consistent across all rollers. If the belt shifts on one roller, the misalignment will accumulate as the belt moves through other rollers, ultimately leading to twisting.

Moreover, properly adjusting the tension of the conveyor belt is crucial to avoid twisting. Insufficient tension can cause the belt to slacken during operation, leading to misalignment and twisting; excessive tension, on the other hand, increases the stress on the belt, making it more likely to twist due to uneven localized forces. Therefore, during installation, professional tensioning devices such as spiral tensioners or counterweight tensioners should be used to precisely adjust the belt tension according to the equipment manual. After adjustment, observe the belt’s performance during operation, looking for any signs of slippage or misalignment, and fine-tune the tension to ensure the belt is properly tensioned.

After installation, the trial run phase is also crucial for identifying and correcting belt twisting issues. During the early stage of the trial run, closely observe the operation of the belt. If any signs of slight twisting are found, stop the system immediately for inspection. It could be that a slight deviation occurred during installation, such as improper roller alignment or uneven belt tension. Any issues discovered should be corrected promptly. Only after ensuring the conveyor belt runs smoothly without twisting during the trial run can it be officially put into production.

Preventing belt twisting during installation requires strict control at multiple stages, including preparation before installation, following installation procedures during the process, and conducting a trial run afterward. By ensuring each step is done correctly, the quality of the belt installation can be guaranteed, laying a solid foundation for its long-term stable operation.