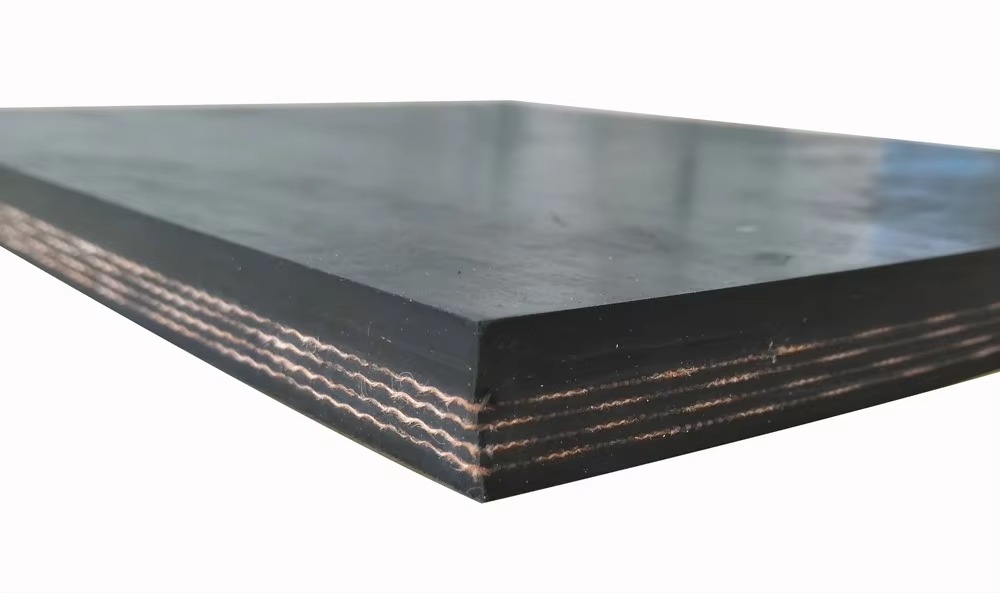

The main types of mining conveyor belts can be categorized as follows:

- Standard Conveyor Belts

- EP Conveyor Belts (Polyester-Nylon): Suitable for general material transportation.

- NN Conveyor Belts (Nylon-Nylon): Offers good tensile strength and elasticity, suitable for medium load transportation.

- Flame Retardant Conveyor Belts

- FR Conveyor Belts: Used in coal mines and flammable environments, with flame retardant properties.

- MSHA Conveyor Belts: Compliant with the U.S. Mine Safety and Health Administration (MSHA) flame retardant standards, used in coal mines.

- High Temperature Resistant Conveyor Belts

- High Temperature EP Belts: Suitable for transporting materials in high-temperature environments, commonly used in steel, metallurgy, and other industries.

- Hot Vulcanized Belts: Suitable for transporting materials at higher temperatures, with excellent heat resistance.

- Tear-Resistant Conveyor Belts

- Tear-Resistant EP Belts: Suitable for transporting large and sharp materials, such as ore and crushed stones.

- Tear-Resistant NN Belts: Also suitable for materials that are prone to tearing and breaking.

- Oil-Resistant Conveyor Belts

- Oil-Resistant EP Belts: Designed for transporting materials containing oil, commonly used in petroleum and chemical industries.

- Acid and Alkali Resistant Conveyor Belts

- Acid and Alkali Resistant Belts: Suitable for transporting chemically corrosive materials, commonly used in chemical and metallurgical industries.

- Chevron Conveyor Belts

- Designed for transporting materials at steep angles, with V-shaped or chevron patterns on the surface to prevent material slippage, commonly used in sand, gravel, and mining industries.

- Refrigeration Conveyor Belts

- Cold-Storage Belts: Suitable for low-temperature environments, commonly used in cold storage warehouses.

- Specialty Conveyor Belts

- Fire-Resistant Belts: Used in high fire-risk environments, capable of preventing the spread of fire.

- Antistatic Conveyor Belts: Used in environments where static control is required.

Each type of conveyor belt is designed for specific operational conditions and environments, and the choice should be based on material characteristics, operating conditions, and load requirements.