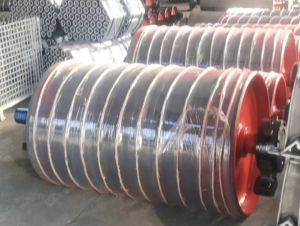

Spiral idlers have the following functions in conveyor belts:

- Spiral idlers prevent adhesion of the conveyor belt in environments that carry sticky or wet materials. They feature non-stick rollers, strong self-cleaning ability, and resistance to belt adhesion;

- Spiral idlers fundamentally solve common problems in belt conveyors, such as corrosion, sticky rollers, belt misalignment, and tearing;

- Spiral idlers have a novel structure, are easy to install and maintain, ensure stable conveying, reduce roller adhesion, produce low noise, have low energy consumption, and extend the lifespan of the conveyor belt;

- Spiral idlers have strong automatic belt alignment capabilities and protect against the twisting and tearing of rubber conveyor belts;

5. Additionally, they extend the lifespan of the conveyor belt, save energy, significantly reduce production costs, and improve economic benefits. Specific size parameters and other specifications can be modified or redesigned based on user requirements or actual usage.