The Importance of Conveyors in Modern Industry

Conveyors are one of the most crucial pieces of equipment in modern industries, widely used in various production, processing, logistics, and storage systems. Through continuous mechanical operation, they enable automated material transportation, significantly improving production efficiency, reducing labor costs, and enhancing product quality. Whether in mining, chemical, food, machinery manufacturing, or in e-commerce and logistics, conveyors play an indispensable role.

1. Types and Applications of Conveyors

Conveyors come in various types based on different application needs. Common types include belt conveyors, roller conveyors, chain conveyors, and screw conveyors. Each type adapts to different material transportation needs depending on working principles and environmental conditions.

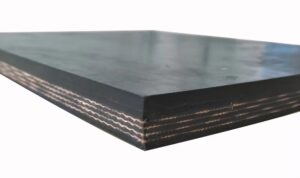

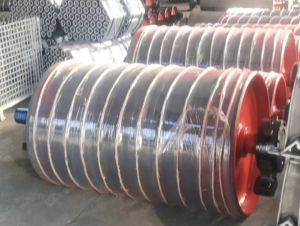

- Belt Conveyors: One of the most common types, suitable for transporting bulk materials or small items. They are widely used in industries such as mining, coal, steel, fertilizer, and food.

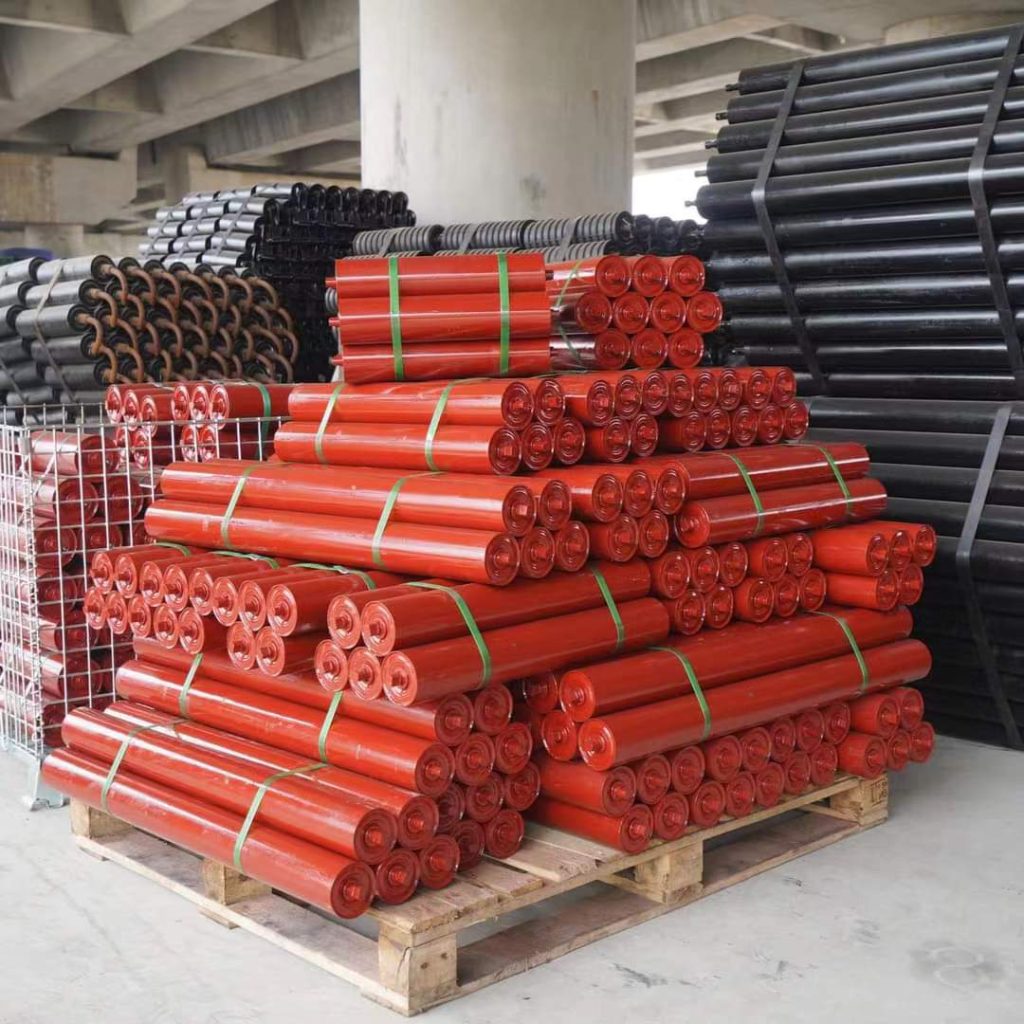

- Roller Conveyors: Ideal for transporting small items, especially in production lines and warehouse management, for handling boxes, bags, parts, etc.

- Chain Conveyors: Mainly used for transporting heavy items, suitable for large objects or materials requiring greater pulling force, often used in the automotive manufacturing industry and heavy material handling.

- Screw Conveyors: Used for transporting powdery, granular, or viscous materials, particularly for short-distance material transfer.

2. Advantages of Conveyors

- Increased Production Efficiency: Automated conveyor systems enable continuous, stable material transportation, eliminating downtime and errors caused by manual handling, thus improving work efficiency.

- Labor Cost Savings: The use of conveyors reduces the need for manual handling, effectively saving labor costs and reducing safety risks associated with manual operations.

- Enhanced Material Management: Conveyors can efficiently integrate material transportation systems with production lines, storage, and other facilities, helping with precise material management and scheduling.

- Versatility: Different types of conveyors can be customized according to customer needs, adapting to various complex working environments and handling different types of materials.

- Reduced Material Loss During Transportation: Conveyors provide smooth transport, minimizing the risk of material damage, especially in industries like food processing, chemicals, and pharmaceuticals where product quality is a top priority.

3. How to Choose the Right Conveyor?

When choosing a conveyor, companies should consider the following factors:

- Material Characteristics: The characteristics of the materials, such as weight, shape, size, and moisture content, will influence the choice of conveyor. For example, materials with a lot of dust are better suited for conveyors with higher sealing, while materials requiring corrosion resistance should be handled by conveyors made of stainless steel.

- Transport Distance and Angle: For long-distance and steep incline transport, conveyors need to have higher load capacity and durability.

- Production Environment: The choice of conveyor also needs to take into account the temperature, humidity, and dust conditions in the production environment to ensure the conveyor can operate stably in various environments.

- Load Capacity: Different conveyors have different load capacities. The choice should be based on the weight and quantity of the material to be transported.

- Maintenance and Care: Selecting conveyors that are easy to maintain and service helps reduce downtime and extend the lifespan of the equipment.

4. Future Trends

With advancements in technology, the technology behind conveyors is continuously evolving. In the future, intelligent and automated conveyor systems will become mainstream. Conveyors integrated with IoT, AI, and other advanced technologies will be able to monitor various parameters in real-time and adjust automatically according to production needs. Additionally, the development of environmentally friendly conveyors will be an important focus, aiming to reduce energy consumption and improve resource utilization.

Overall, conveyors play a significant role not only in improving production efficiency and reducing costs but also in driving the automation of production, material management, and environmental protection. With continuous technological advancements, conveyors will play a greater role across more industries, promoting the shift toward intelligent and automated processes in various sectors.

This article helps to better understand the importance and applications of conveyors in modern industries. Let me know if you need further assistance!