、

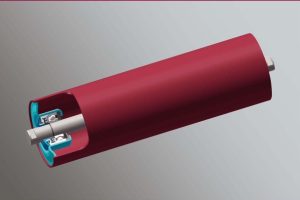

Fire Resistant Conveyor Belts

Key Features:

- Flame Retardancy: This is the most crucial characteristic. The materials are specially treated or formulated to resist ignition or self-extinguish quickly when exposed to open flames or high temperatures. This effectively prevents the spread of fire and reduces fire hazards.

- Safety: In industries with high fire safety requirements, such as coal mining, chemical processing, and power generation, using fire-resistant conveyor belts is a vital measure to ensure production safety and minimize accidents caused by belt fires.

Structural Characteristics:

- Fire Resistant Cover Rubber: The cover rubber is a key component for flame retardancy. This is typically achieved by:

- Adding Flame Retardants: Incorporating specific fire-retardant chemicals into the rubber compound to impart flame-resistant properties.

- Using Special Synthetic Rubbers: Some synthetic rubbers inherently possess a degree of flame resistance.

- Fire Resistant Carcass: To ensure overall fire resistance, the carcass material also needs to be flame retardant. Common fire-resistant carcass materials include:

- Flame Retardant Impregnated Fabrics: Treating the fabric core with special fire-retardant agents.

- Flame Resistant Synthetic Fibers: Using synthetic fibers with inherent flame-resistant properties for weaving the carcass.

- Anti-Static Properties (in some fire-resistant belts): Especially in environments prone to gas explosions, such as coal mines, fire-resistant conveyor belts often also have anti-static properties to prevent the buildup of static electricity that could cause accidents. This is achieved by adding conductive materials to the rubber compound.

Main Types (by application area or standard):

- Conveyor Belts for Coal Mining (MT668 Standard): These must meet the requirements of the Chinese coal industry standard MT668, including flame retardancy, anti-static properties, impact resistance, and tear resistance. They may be further categorized into different types (e.g., PVC type, PVG type, rubber type) based on structure and performance.

- General Fire Resistant Conveyor Belts: Suitable for other industries with fire safety requirements, such as chemical processing, power generation, and metallurgy. Their flame-retardant properties may comply with international standards (e.g., ISO 284) or other industry-specific standards.

- Steel Cord Fire Resistant Conveyor Belts: Combine the high strength of steel cord carcasses with fire-resistant properties, suitable for long-distance, high-strength conveying applications with fire safety concerns.

- Fabric Carcass Fire Resistant Conveyor Belts: Available in various types depending on the carcass material (e.g., EP, NN, CC) and the level of fire resistance.

Main Application Areas:

- Underground Coal Mines: The primary application area for fire-resistant conveyor belts.

- Chemical Industry: Facilities conveying flammable or toxic substances.

- Power Generation Industry: Coal handling systems in power plants.

- Metallurgical Industry: High-temperature operations with fire hazards.

- Grain Silos, Wood Processing Plants, etc.: Locations with dust explosion risks.

Considerations for Selecting Fire Resistant Conveyor Belts:

- Required Fire Resistance Level and Standards: This is the most critical factor and must comply with the safety regulations of the application industry.

- Properties of the Conveyed Material: Including the type of material, temperature, and any corrosive properties.

- Conveying Capacity and Conditions: Including conveying distance, inclination angle, and operating speed.

- Carcass Strength: Select the appropriate carcass strength based on the conveying load.

- Cover Rubber Properties: In addition to fire resistance, other properties like abrasion resistance, heat resistance, and chemical resistance may be required.

- Need for Anti-Static Properties: Especially in flammable and explosive environments.

Summary:

Fire-resistant conveyor belts are specialized conveyor belts with inherent flame-retardant properties, crucial for industrial environments with fire hazards. Selection must strictly adhere to relevant safety standards and regulations, and the appropriate fire resistance level, carcass material, cover rubber properties, and dimensions should be chosen based on specific application requirements to ensure production safety and efficient operation. Consulting with professional conveyor belt suppliers is highly recommended for the most suitable selection advice.