Steep Incline Sidewall Conveyor Belt

The steep incline sidewall conveyor belt is a special type of conveyor belt designed for steep or vertical conveying, widely used in material transportation systems. Its unique structural design and excellent performance make it one of the essential pieces of equipment for addressing high-efficiency conveying needs in confined spaces. The following is a comprehensive introduction to its structural features, technical advantages, and application fields.

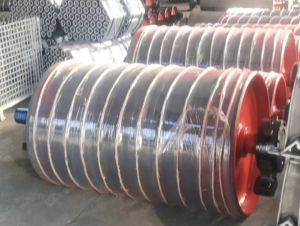

1. Structural Features of the Steep Incline Sidewall Conveyor Belt

Base Belt

Made from high-strength, highly elastic, and wear-resistant material, the base belt is used to carry materials and ensure the overall strength of the conveyor belt. It typically uses wear-resistant rubber and canvas as base materials, ensuring long-term use without deformation.

Sidewalls

The sidewalls are set on both sides of the conveyor belt, made of flexible and tear-resistant materials to prevent materials from sliding off. The height of the sidewalls can be adjusted according to the incline angle, adapting to different conveying needs.

Crossbars

The crossbars (also known as partition bars) are perpendicular to the conveyor belt and are used to fix and separate materials to prevent sliding or piling. The crossbars come in various shapes (such as T-type and TC-type) and are designed to meet the characteristics of different materials.

2. Technical Advantages of the Steep Incline Sidewall Conveyor Belt

Steep Incline Conveying

The maximum conveying incline can reach up to 90°, breaking through the conventional incline limitations of conveyor belts and significantly saving space.

High Conveying Efficiency

The design of the sidewalls and crossbars keeps materials stable during the conveying process, reducing material fall-back and improving conveying efficiency.

Strong Adaptability

This conveyor belt can transport powdery, granular, bulk, and mixed materials, suitable for a wide range of material types.

Durable and Wear-Resistant

The base belt and sidewall materials have excellent wear resistance, heat resistance, and corrosion resistance, making them suitable for harsh working conditions.

Easy Installation

It can be installed on existing conveyor systems without additional modifications, greatly reducing installation costs.

3. Application Fields of the Steep Incline Sidewall Conveyor Belt

Mining and Coal Industry

Used for transporting bulk materials such as ores and coal, especially suitable for underground conveying and locations with significant height differences.

Chemical and Building Materials Industry

Ideal for conveying powdery or granular materials such as cement, limestone, and fertilizers, meeting various process requirements.

Ports and Terminals

Used in confined spaces for unloading cargo in ship holds, warehouse loading, and achieving efficient material transport.

Agriculture and Food Industry

Used to transport light materials such as grain and seeds, meeting environmental and hygiene requirements.

4. Selection and Maintenance of the Steep Incline Sidewall Conveyor Belt

Selection Tips

Choose the appropriate sidewall height and crossbar type based on the particle size, density, and conveying height of the material. Ensure the base belt material meets operational requirements, such as heat resistance, oil resistance, or acid-alkali resistance.

Maintenance

Regularly check for wear on the sidewalls and crossbars, replacing damaged components promptly. Clean material residues from the base belt and crossbars to prevent long-term accumulation, which could affect performance. Lubricate the drive system and tensioning system to ensure smooth operation of the equipment.

5. Future Development Trends of the Steep Incline Sidewall Conveyor Belt

High-Performance Materials

The development of new materials will further enhance the wear resistance, high-temperature resistance, and aging resistance of the conveyor belt.

Intelligent Monitoring

Integrating sensors and monitoring systems will allow for real-time monitoring of the conveyor belt’s operational status, improving reliability.

Eco-Friendly Design

Adopting more environmentally friendly manufacturing processes and materials to meet the needs of green industrial development.

6. Conclusion

The steep incline sidewall conveyor belt, with its high efficiency, adaptability to steep angles, and flexibility, has become the preferred equipment for solving complex conveying scenarios. In the future, with advancements in material technology and changes in industrial demand, the steep incline sidewall conveyor belt will play an increasingly important role across various fields.

For more information about our products or selection advice, feel free to contact our technical team. We are committed to serving you!