Engineering-Grade Rollers: Enhancing Conveyor System Efficiency and Durability

Engineering-grade rollers are essential components in conveyor systems, especially in high-load and high-intensity environments, where they play a critical role. This article will delve into the definition, features, applications, and how to select the right roller to improve the efficiency and reliability of conveyor systems.

1. What Are Engineering-Grade Rollers?

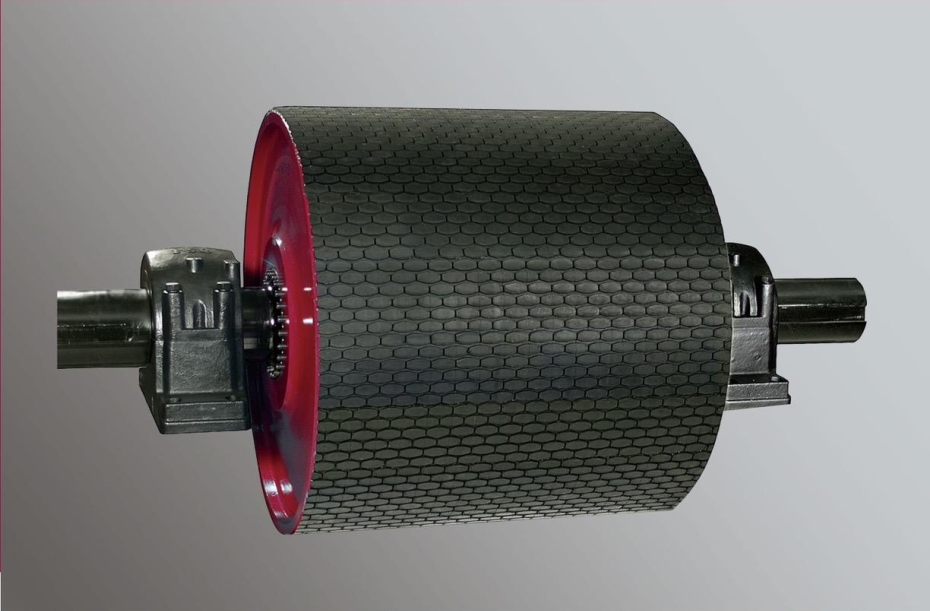

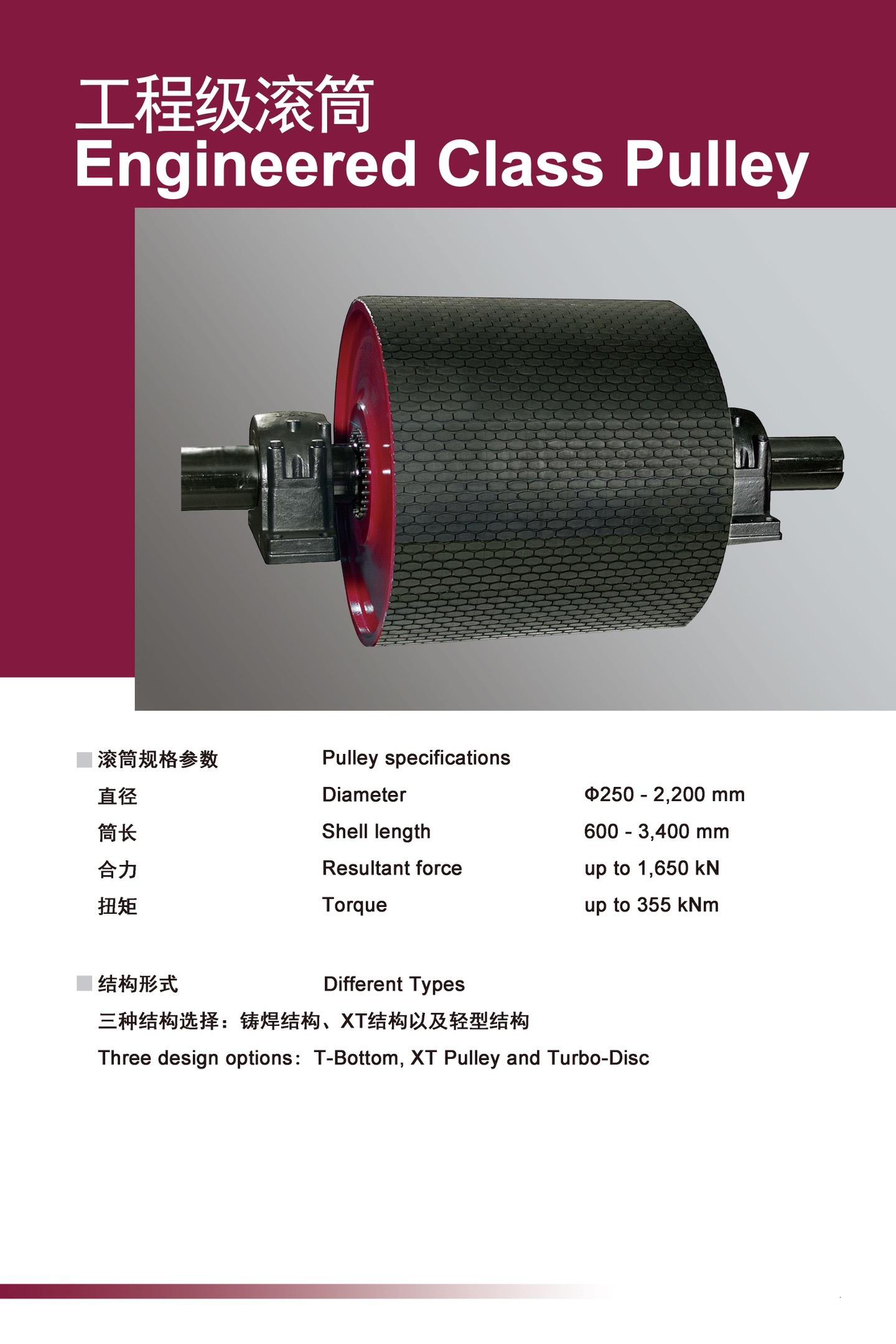

Engineering-grade rollers are designed for conveyor belt systems that endure heavy loads and harsh working conditions. Compared to regular rollers, engineering-grade rollers have higher strength and wear resistance, enabling them to perform consistently under severe conditions. Their design takes into account not only load capacity but also friction performance, energy efficiency, and extended lifespan.

2. Features of Engineering-Grade Rollers

- High Load Capacity: Engineering-grade rollers are made from high-strength materials (such as steel or aluminum alloys) to withstand greater pressure and weight, making them suitable for heavy-duty material transport.

- Wear Resistance: The surface of the rollers is often treated with special coatings or heat treatments to enhance wear resistance. This feature is crucial for systems operating in high-frequency or complex environments.

- Low Friction Resistance: To improve conveyor efficiency, engineering-grade rollers are designed with low friction, reducing the resistance between the conveyor belt and the roller, thus lowering energy consumption.

- Long Lifespan: Manufactured with high-quality materials and precise processing techniques, engineering-grade rollers typically offer longer service life compared to regular rollers, reducing the frequency of maintenance and replacements.

- Corrosion Resistance: In certain environments, such as mines or chemical plants, the corrosion resistance of rollers is essential. Engineering-grade rollers are often made with anti-corrosion materials or coatings to ensure stable operation in harsh environments.

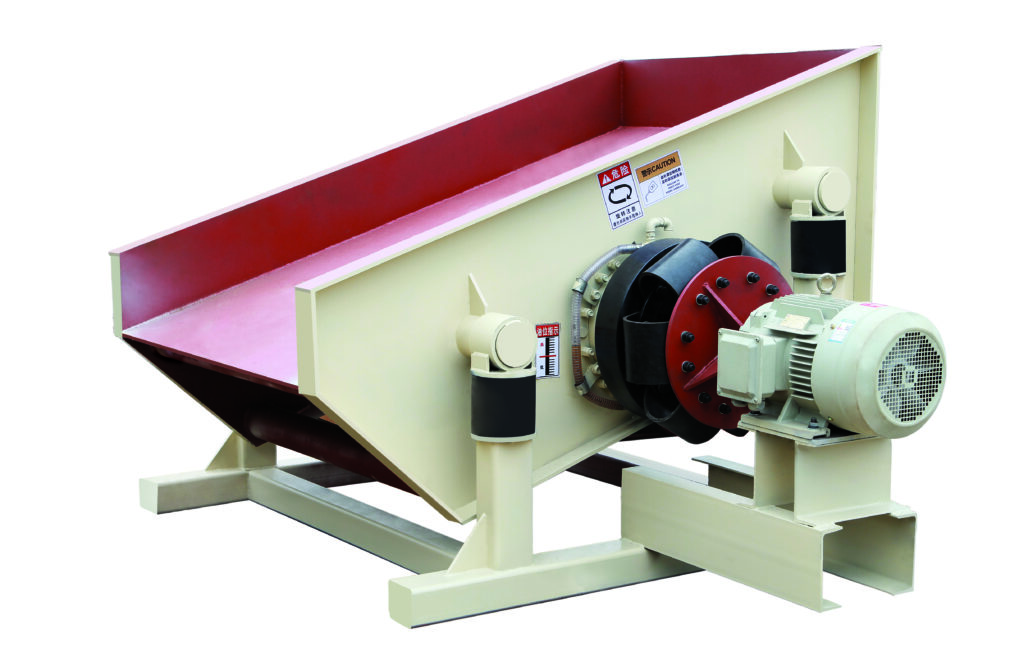

3. Applications of Engineering-Grade Rollers

Engineering-grade rollers are widely used in conveyor systems that require high strength and continuous operation. Here are some typical application fields:

- Mining Industry: The transport of heavy materials such as ore and coal requires rollers that can bear significant loads. Engineering-grade rollers play a crucial role in conveyor systems in the mining industry.

- Construction Industry: In transporting construction materials, rollers must support heavy loads and endure frequent operations. Engineering-grade rollers meet these needs effectively.

- Logistics and Warehousing: The logistics industry requires efficient and stable conveyor systems, and engineering-grade rollers offer excellent performance to ensure smooth material flow.

- Steel Manufacturing: In steel production, heavy and high-temperature materials need to be conveyed. Engineering-grade rollers provide strong support, ensuring the stability of the conveyor system.

4. How to Choose the Right Engineering-Grade Roller?

Choosing the appropriate engineering-grade roller involves considering the following factors:

- Load Capacity: Select rollers with suitable load-bearing capacity according to the weight of the materials being transported, ensuring the rollers do not become overloaded, which could affect the stability of the system.

- Working Environment: Choose rollers that meet specific environmental requirements, such as heat resistance, corrosion resistance, or water and dust resistance, depending on the working conditions.

- Wear Resistance and Lifespan: Select rollers with higher wear resistance and longer service life based on the frequency of conveyor system use to reduce maintenance and replacement costs.

- Size and Installation Requirements: Ensure the roller size matches the specifications of the conveyor belt and meets installation requirements for optimal performance.

5. Conclusion

Engineering-grade rollers are critical components in heavy-duty conveyor systems, offering high load capacity, wear resistance, low friction, and long lifespan. They are widely used in industries such as mining, construction, steel manufacturing, and logistics, ensuring efficient and stable operation of conveyor systems. When selecting engineering-grade rollers, it is essential to consider load capacity, working environment, wear resistance, and other factors to ensure the long-term, high-efficiency performance of the system.