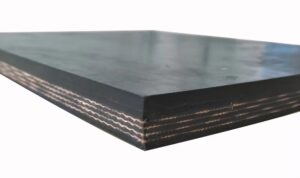

Chevron Conveyor Belt / Herringbone Conveyor Belt

Key Features:

- Belt surface with “chevron” (V-shaped or <-shaped) cleats: This is the most defining characteristic. The height and shape of these cleats can be designed based on the properties of the conveyed material and the angle of inclination.

- Primarily used for steep incline conveying: The chevron cleats effectively increase the friction between the material and the conveyor belt, preventing material slippage during inclined transport. Therefore, it is very suitable for applications with large conveying angles.

- Improves conveying efficiency and stability: Compared to ordinary flat belts, chevron conveyor belts can stably convey materials at steeper angles, improving conveying efficiency and reducing material spillage.

Structural Components:

- Carcass: Similar to ordinary conveyor belts, it provides strength and load-bearing capacity. Common types include fabric carcasses (such as cotton canvas, nylon, polyester, etc.) and steel cord carcasses.

- Cover Rubber: The top cover rubber comes into contact with the material and needs to have certain properties such as wear resistance and impact resistance. The bottom cover rubber contacts the pulleys.

- Chevron Cleats: Firmly bonded to the belt body through vulcanization or other methods, these are the key components of the chevron conveyor belt. The height, width, angle, and spacing of the cleats are designed according to application requirements.

Main Application Areas:

- Mining: Conveying bulk materials such as coal and ore.

- Metallurgy: Conveying coke, sinter, and other high-temperature materials.

- Construction: Conveying sand, gravel, cement, concrete, etc.

- Chemical Industry: Conveying various powdery and granular materials.

- Agriculture: Conveying grains, feed, etc.

- Ports and Docks: Conveying bulk cargo.

Advantages:

- Strong steep incline conveying capability: Significantly increases the conveying angle, saving space.

- Prevents material slippage: Ensures the stability and safety of the conveying process.

- Increases conveying capacity: Can convey more material with the same belt width.

- Strong adaptability: Different shapes and heights of cleats can be designed according to different materials and conveying requirements.

Disadvantages:

- Relatively high manufacturing cost: Manufacturing process is more complex compared to ordinary flat belts.

- Potentially higher maintenance requirements: Regular inspection of cleat wear is necessary.

- Not suitable for conveying large, lumpy materials: Cleats may obstruct the passage of large materials.

In summary, the chevron conveyor belt is a very practical and efficient conveying equipment for applications requiring steep incline conveying of bulk materials.