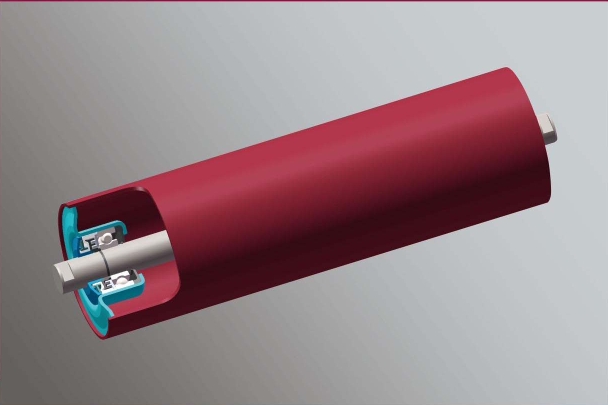

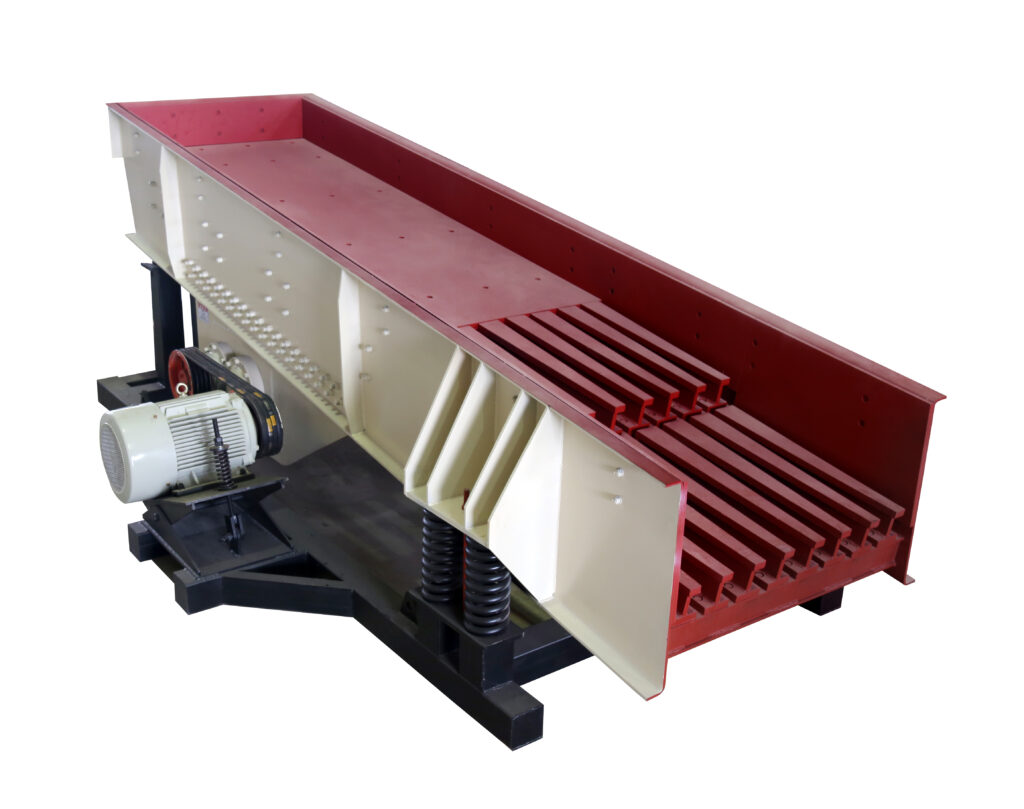

Conveyor rollers are essential components of conveyor systems that provide support and guidance to the conveyor belt. They are cylindrical devices that rotate freely, allowing the belt to move smoothly over them. The choice of conveyor rollers depends on various factors such as the type of material being conveyed, the speed of the conveyor, and the environmental conditions.

Types of Conveyor Rollers

- Standard Rollers: These are the most common type and are used for general-purpose conveying.

- Impact Rollers: Designed to handle heavy loads and impact forces.

- Spiral Rollers: Used to convey materials up or down inclined conveyors.

- Magnetic Rollers: Used to convey ferrous materials.

- Idler Rollers: Support the return run of the conveyor belt.

Functions of Conveyor Rollers

- Support: Provide support to the conveyor belt and the materials being conveyed.

- Guidance: Guide the conveyor belt along a specific path.

- Reduction of Friction: Reduce friction between the belt and the conveyor frame.

- Absorption of Shock: Impact rollers help to absorb shock loads.

Factors Affecting Roller Selection

- Material Handling: The type of material being conveyed determines the required roller diameter, material, and surface finish.

- Conveyor Speed: Higher speeds may require larger diameter rollers or special bearings.

- Environmental Conditions: Temperature, humidity, and corrosive substances can affect the choice of roller material.

- Load Capacity: The weight of the material being conveyed determines the required roller capacity.

Would you like me to elaborate on any specific aspect of conveyor rollers, such as:

- Different types of roller bearings

- Roller materials and their properties

- Roller alignment and maintenance

- Roller installation techniques

- The role of conveyor rollers in specific industries (e.g., mining, food processing)