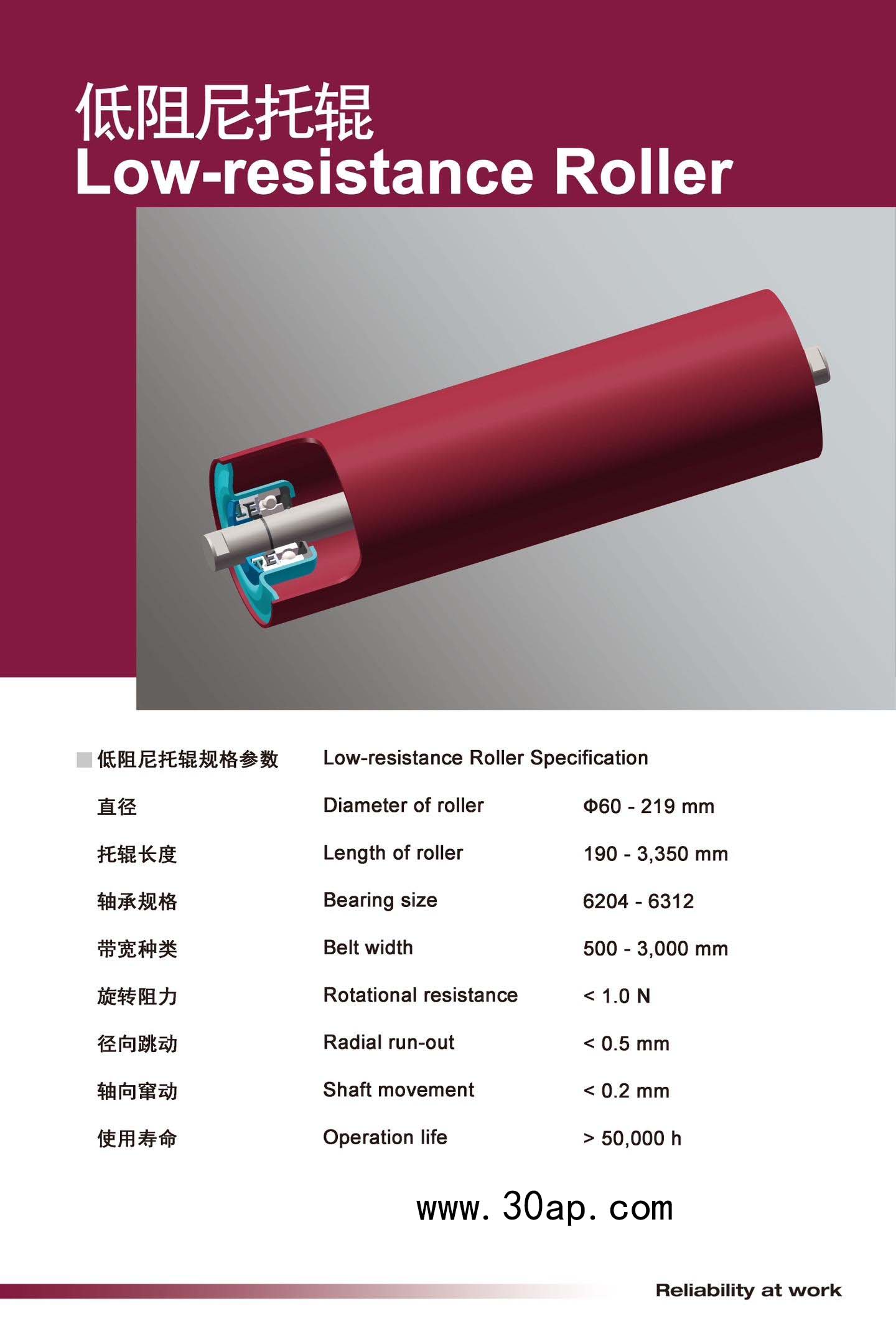

Low-damping Rollers are designed to reduce friction resistance, minimize energy loss, and improve the operational efficiency of conveyor belts. They achieve this by optimizing design, material selection, and manufacturing processes to decrease the friction between the roller and the conveyor belt, thus improving the overall performance and reducing energy consumption, while extending equipment lifespan.

Characteristics of Low-damping Rollers:

- Reduced Friction Resistance: Achieved through the use of low-friction materials or special structures, decreasing the friction between the roller and the conveyor belt.

- Improved Conveyor Efficiency: The smoother operation of the conveyor belt due to reduced friction results in enhanced overall efficiency.

- Extended Equipment Lifespan: Reduced friction leads to less wear, thereby prolonging the lifespan of both the rollers and the conveyor belts.

- Energy Efficiency: Lowering friction directly reduces energy consumption, especially for long-distance and heavy-load transportation.

- Low Noise: The design also helps in reducing operational noise, which is beneficial for a quieter working environment.

Common Applications:

- Mining conveyors, coal transportation, steel manufacturing, petrochemical industries, and other high-intensity, long-duration operations.

- Suitable for conveyor systems with high-efficiency and energy-saving requirements.

The specific materials, designs, and manufacturing techniques for low-damping rollers may vary depending on the application requirements, but their primary goal remains to enhance conveyor efficiency and reduce energy consumption.