Application fields: Sand and gravel yards, mining operations, coal mining, concrete batching plants, dry mortar, power plant desulfurization, quartz sand

Applicable materials: Limestone, bluestone, coal gangue, shale, gravel, gneiss

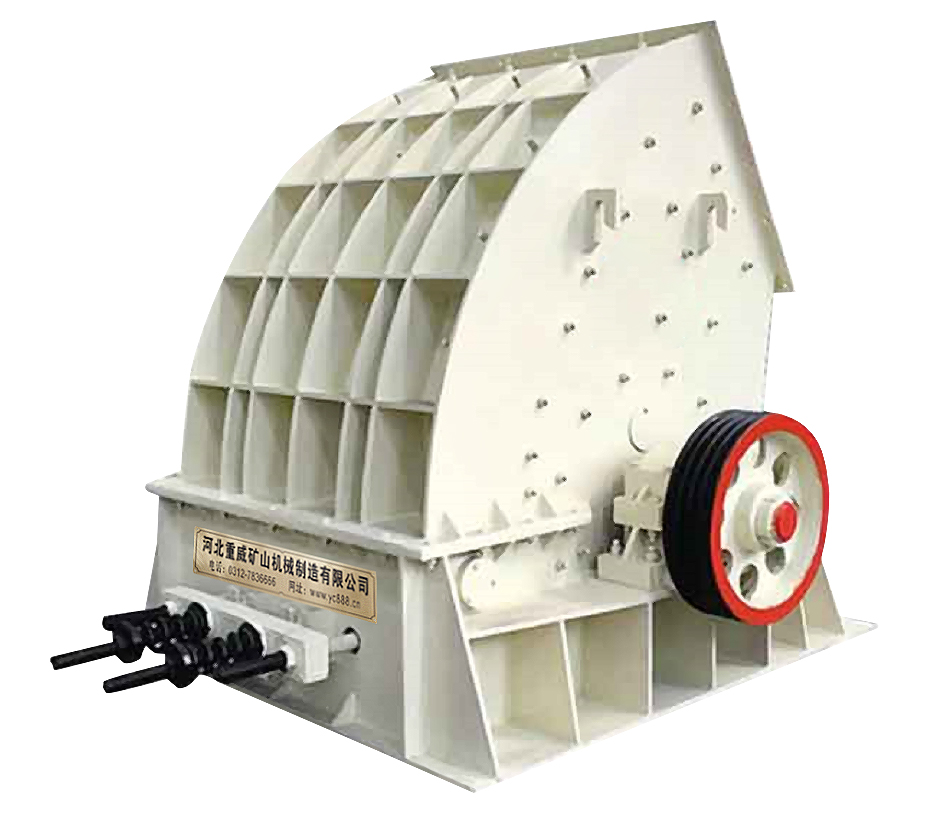

The heavy-duty hammer crusher, also known as the heavy hammer crusher, is a device designed for crushing high-hardness and large-sized materials. It is widely used in industries such as mining, building materials, power generation, and chemicals. The machine works by using high-speed rotating hammers to impact and crush materials. Compared to traditional crushing equipment, the heavy-duty hammer crusher offers the following advantages:

-

High Efficiency and Energy Saving: Through optimized design and materials, it reduces energy consumption and increases crushing efficiency, especially for handling large, hard materials.

-

Multi-functional: It can complete the crushing and shaping of large materials in one step, eliminating the need for secondary crushing and reducing production costs.

-

Wide Application Range: It is suitable for crushing brittle materials with a compressive strength of up to 150 MPa, such as limestone, coal gangue, bluestone, shale, etc., and is widely used in sand and gravel yards, mining operations, and coal mining.

-

Simple Structure: The compact structure makes it easy to operate and maintain, reducing operating costs.

-

High Durability: Made with high wear-resistant materials, it extends the service life of the equipment and reduces maintenance frequency.

The heavy-duty hammer crusher is especially suitable for processing materials with a production capacity of less than 500 tons per hour. It can effectively replace the traditional jaw crusher + impact crusher two-stage crushing process, achieving crushing and shaping in one machine, simplifying the production process.

The heavy-duty hammer crusher, commonly known as the heavy hammer crusher, is a newly developed type of hammer crusher based on the development trends of the crushing industry and experimental data from stone crushing test bases. It is suitable for crushing brittle materials with a compressive strength of no more than 150 MPa, such as limestone, bluestone, coal gangue, shale, gravel, gneiss, and others. For processing capacities below 500 tons per hour, it can replace the traditional jaw crusher + impact crusher two-stage crushing model, achieving crushing and shaping in one machine without the need for secondary crushing.