High Abrasion Resistant Conveyor Belts

Key Features:

- Exceptional Abrasion Resistance: This is the most crucial characteristic. The cover rubber utilizes a specially formulated rubber compound with extremely high abrasion resistance, capable of withstanding long-term friction and scratching from sharp, rough materials.

- Extended Service Life: Due to their superior abrasion resistance, these belts significantly extend operational lifespan, reducing replacement frequency and consequently lowering maintenance costs and downtime.

- Withstand Harsh Operating Conditions: They can operate reliably in severely abrasive environments, such as conveying ore, coal, coke, gravel, and other hard, sharp-edged materials.

Structural Characteristics:

- High Abrasion Resistant Cover Rubber: This is the core of these belts. Abrasion resistance is typically enhanced through:

- Special Rubber Compounds: Utilizing high-abrasion resistant natural rubber, synthetic rubbers (like nitrile rubber, styrene-butadiene rubber, etc.), and incorporating special anti-wear additives.

- High Carbon Black Content: Carbon black is a common reinforcing and anti-wear agent; a high content of high-quality carbon black significantly improves the rubber’s abrasion resistance.

- Incorporation of Other Wear-Resistant Materials: Some high abrasion resistant belts may also include ceramic particles, ultra-high molecular weight polyethylene (UHMWPE), and other more wear-resistant materials.

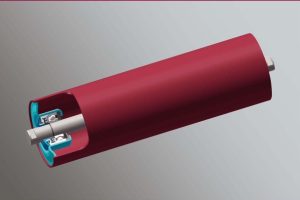

- High-Strength Carcass: To ensure stable operation under heavy loads and high tension, these belts typically use high-strength carcass materials, such as high-strength fabrics or steel cords.

- Excellent Adhesion: Good adhesion strength between the cover rubber and the carcass is essential to prevent delamination during use.

Main Application Areas:

- Mining: Conveying various ores, rocks, and concentrate powders.

- Metallurgy: Conveying coke, sinter, slag, and other high-temperature and highly abrasive materials.

- Quarries: Conveying sand, gravel, aggregates, etc.

- Power Plants: Conveying coal, ash, etc.

- Cement Plants: Conveying cement clinker, limestone, etc.

- Ports and Docks: Conveying bulk cargo such as mineral sands and coal.

Considerations for Selecting High Abrasion Resistant Conveyor Belts:

- Properties of the conveyed material: Including hardness, particle size, shape, and the presence of sharp edges.

- Conveying capacity and speed: Different capacities and speeds place varying demands on the belt’s abrasion resistance.

- Operating environment: Whether there are special environmental factors such as high temperatures or corrosion.

- Economics: While the initial cost may be higher, the longer service life of high abrasion resistant belts can reduce long-term operating costs.

Summary:

High abrasion resistant conveyor belts are specifically designed for conveying materials with high abrasiveness. Through the use of special rubber compounds and structural designs, they significantly extend service life, reduce maintenance costs, and improve production efficiency, making them an ideal choice for industries such as mining, metallurgy, and quarries. When selecting, it is crucial to fully consider the characteristics of the conveyed material and the operating environment to choose the appropriate abrasion resistance grade and model.