The roller of the mine conveyor is the core part of the whole conveying system, which bears the important functions of carrying materials and driving the conveyor belt. Its quality directly affects the operating efficiency and service life of the conveyor.

The main role of the drum:

Load material: Roller and conveyor belt work together to carry and transport ore, coal and other materials.

Drive conveyor belt: The power roller drives the conveyor belt through friction.

Supporting conveyor belt: Rollers and driving rollers support the conveyor belt to ensure smooth operation.

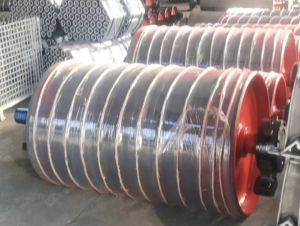

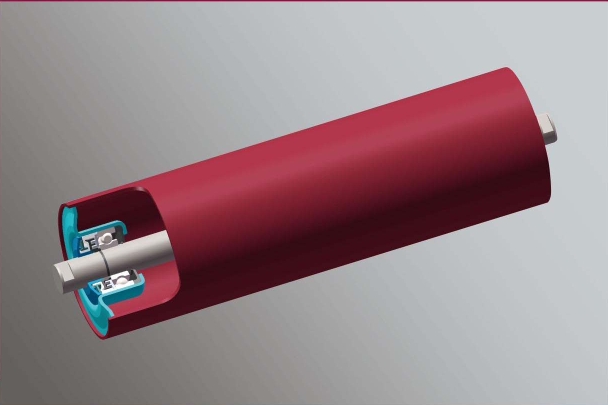

Material and structure of roller:

The material of the roller is usually steel, and the surface can be galvanized, rubber coated, etc., to improve wear resistance, corrosion resistance and adhesion. The structure of the drum mainly includes barrel, bearing, seal and so on.

Opens in a new window

m.zidongbaozhuangxian.com

Structure diagram of mine conveyor roller

Classification of rollers:

According to different functions, rollers can be divided into driving rollers, reversing rollers, rollers and so on.

Driving drum: provides power to drive the conveyor belt to run.

Reversing drum: used to change the direction of the conveyor belt.

Rollers: Support the conveyor belt and reduce friction.

Opens in a new window

chinese.alibaba.com

Different types of mine conveyor rollers

Maintenance and maintenance of rollers:

Regular inspection: Check whether the surface of the roller has wear, cracks and other phenomena.

Cleaning and maintenance: Remove the attachments on the surface of the drum and keep it clean.

Lubrication maintenance: regular lubrication of roller bearings.

Drum selection precautions:

Material characteristics: Select the appropriate roller material according to the abrasive and corrosive properties of the material.

Throughput: Select the appropriate drum diameter and number according to throughput.

Conveying distance: Select the appropriate drum distance according to the conveying distance.

Conclusion:

Roller is an important part of mine conveyor, and its performance directly affects the efficiency and reliability of the whole conveying system. Therefore, when selecting and using rollers, various factors should be considered comprehensively, and daily maintenance work should be done.

(More expertise on drums can be added as needed, such as drum balance, vibration issues, and the application of new materials in drum manufacturing.)

Warm reminder:

Picture suggestion: More pictures can be added about different parts of the drum, different materials, and installation positions on the conveyor to help readers better understand.

Professional terms: Adding some professional terms to the article can increase the professionalism of the article, but pay attention to easy to understand and avoid being too obscure.

Case analysis: The application characteristics and advantages and disadvantages of different types of mine conveyor rollers can be introduced in combination with actual cases.