Conveyor Belts and Rollers: The Backbone of Material Handling

In modern industrial settings, conveyor systems play an indispensable role. Conveyor belts and rollers, as the core components, are the backbone of efficient material handling operations. Whether it’s mining, port operations, or manufacturing logistics, conveyor belts and rollers provide a solid foundation for high-performance operations.

Conveyor Belts

Conveyor belts serve as the primary carriers of materials. Their materials and structures vary based on the specific application. For instance, steel cord conveyor belts, known for their high strength and wear resistance, are commonly used in mining and heavy industries. EP conveyor belts, on the other hand, are widely used in medium and short-distance conveying due to their excellent flexibility and tensile strength. Additionally, PVC/PVG flame-resistant conveyor belts are extensively used in underground coal mines and other high-safety environments.

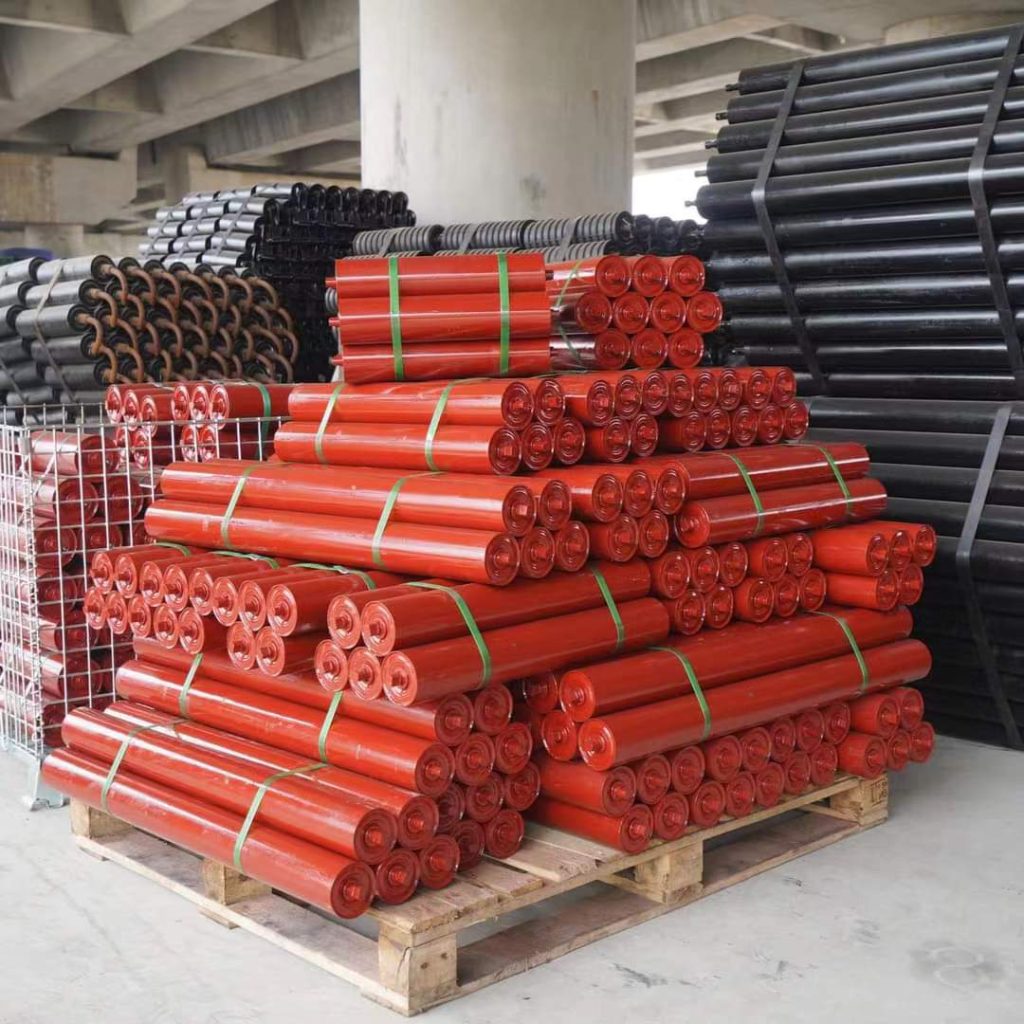

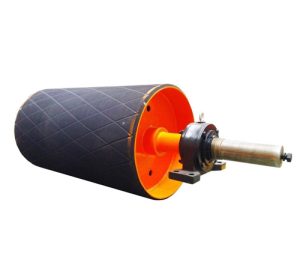

The Role of Conveyor Rollers

Conveyor rollers are crucial components that support the conveyor belt and reduce operational resistance. Common types of rollers include troughed rollers, impact rollers, and self-cleaning rollers. Troughed rollers are suitable for conveying loose materials; impact rollers mitigate the impact of falling materials in the discharge area, protecting the conveyor belt; and self-cleaning rollers effectively remove adhering materials, ensuring smooth system operation.

Synergy Between Conveyor Belts and Rollers

The close cooperation between conveyor belts and rollers is essential for the efficient operation of the entire conveying system. Rollers not only provide stable support for the conveyor belt but also extend its service life. To adapt to various working conditions, the materials, structural design, and sealing of rollers need to be optimized based on specific requirements.

Application Areas

Conveyor belts and rollers find extensive applications in numerous industries:

- Mining: For high-strength, long-distance transportation of ores and coal.

- Port Logistics: For loading and unloading bulk materials.

- Manufacturing: For automated material handling in production lines.

- Construction: For transporting sand, cement, and other construction materials.

Conclusion

The innovation and development of conveyor belts and rollers have driven the progress of industrial automation and significantly reduced labor costs for enterprises. In the future, with advancements in technology, conveyor systems will become even more intelligent and efficient, bringing greater convenience to industrial production.

Key points highlighted in the English translation:

- Emphasizes the critical role of conveyor belts and rollers in modern industries.

- Provides a clear explanation of different types of conveyor belts and rollers.

- Highlights the importance of the synergy between belts and rollers.

- Covers a wide range of applications across various industries.

- Discusses the future trends of conveyor systems.