Application fields: Sand and gravel yards, mining operations, coal mining, concrete batching plants, dry mortar, power plant desulfurization, quartz sand

Applicable materials: Limestone, bluestone, coal gangue, shale, gravel, gneiss

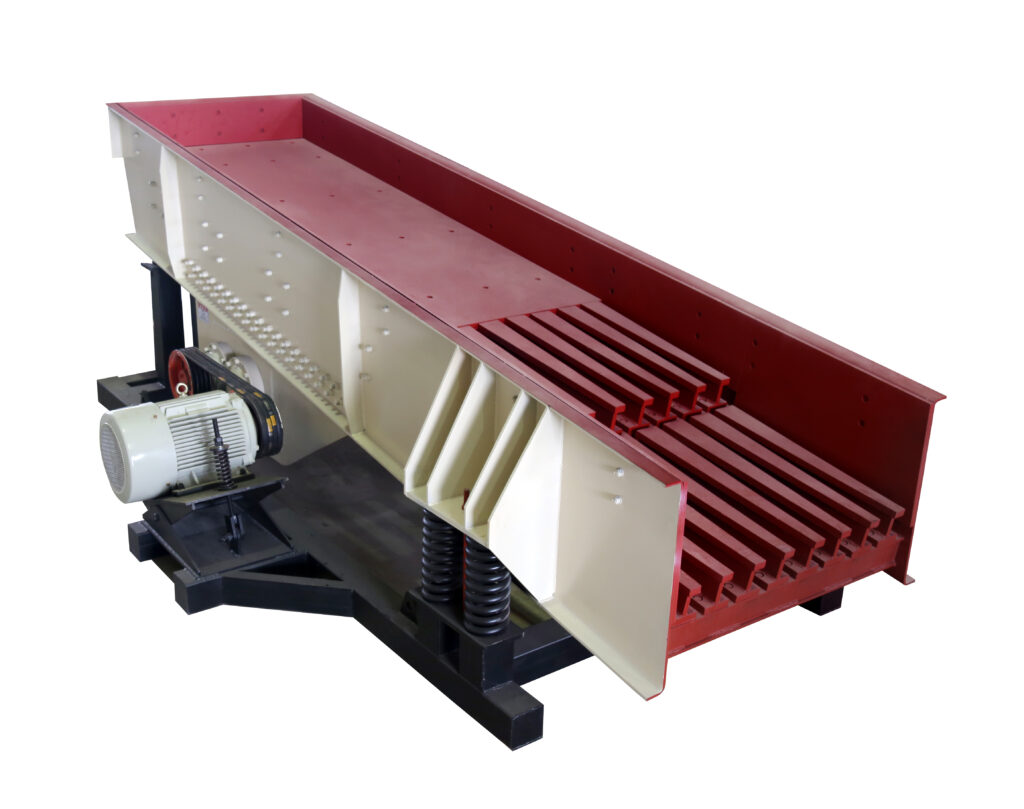

A vibrating feeder is a type of feeding equipment commonly used in industries such as mining, aggregate, and construction. It is designed to transport bulk materials evenly and continuously from a storage hopper to crushers, screens, or other processing equipment. The vibrating feeder operates using vibration generated by an electric motor, ensuring smooth and consistent material flow.

Key Features of Vibrating Feeder:

-

Continuous and Uniform Feeding: The vibrating feeder ensures a steady and consistent flow of material to downstream equipment, preventing overload and maintaining optimal processing efficiency.

-

Adjustable Feeding Rate: The feeding speed and capacity can be adjusted based on production requirements, providing flexibility in material handling.

-

Durable and Reliable: Constructed with high-quality materials, the vibrating feeder is built to handle heavy-duty operations and provide long-lasting performance even in harsh environments.

-

Low Power Consumption: Vibrating feeders are designed to operate efficiently with minimal energy consumption, reducing operational costs.

-

Anti-vibration Design: The feeder is designed to minimize vibrations in the surrounding environment, ensuring stable operations and improved safety.

Applications:

-

Mining Industry: Feeding bulk materials such as ores, coal, and rocks to crushers or other processing equipment.

-

Aggregate Production: Conveying sand, gravel, and crushed stone to screening or washing plants.

-

Food and Chemical Industries: Delivering granules, powders, or liquids to mixers or packaging machines.

-

Recycling and Waste Handling: Feeding materials to separation systems or sorting machines.

Vibrating feeders are essential in ensuring the proper and efficient operation of various processing systems, making them crucial in a wide range of industrial applications.