Conveyor Rollers: Key Components in Conveyor Systems

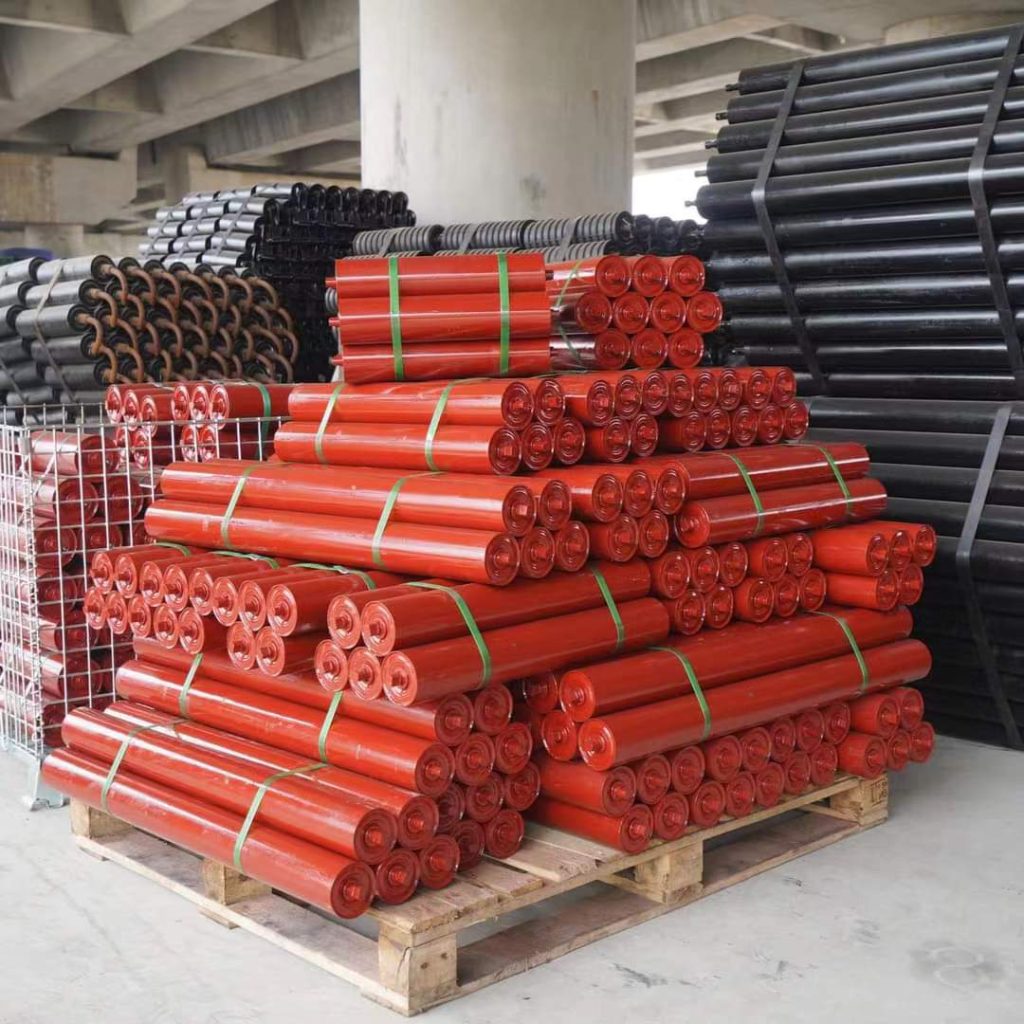

Conveyor rollers are an essential part of conveying equipment, responsible for driving and supporting the smooth operation of the conveyor belt. Their performance directly impacts the operational efficiency and service life of the conveyor system. The rollers shown in the image feature excellent design and sturdy construction, making them widely used in various conveyor equipment.

1. Classification of Rollers

- Drive Rollers: Responsible for transmitting power to the conveyor belt, making it move materials. Typically installed at the head of the conveyor.

- Return Rollers: Used to change the direction of the conveyor belt’s movement, usually located at the tail or in the middle of the conveyor.

2. Structural Features of Rollers

- High-Strength Material: Made from high-quality steel, offering strong impact resistance and wear performance.

- Precision Processing: Using advanced welding and machining techniques to ensure high concentricity and smooth operation of the rollers.

- High-Quality Surface Coating: The roller surface is covered with a rubber layer, increasing friction and preventing the conveyor belt from slipping, thereby improving transmission efficiency.

- Efficient Sealing Performance: The bearing and sealing system is designed to be dustproof and waterproof, making it suitable for various harsh working conditions.

3. Applications

Conveyor rollers are widely used in the following industries:

- Mining Industry: Used for the transportation of ores and coal, carrying heavy loads.

- Metallurgical Industry: Suitable for material transportation in high-temperature environments, such as steel mills.

- Ports and Terminals: For loading and unloading bulk materials.

- Construction Industry: Used for transporting construction materials like sand, gravel, and cement.

4. Maintenance and Care

To extend the service life of the rollers and maintain their high efficiency, the following aspects should be regularly checked:

- Check if the rubber layer on the roller surface shows signs of wear or aging.

- Inspect the bearings to ensure smooth operation and check for abnormal sounds or vibrations.

- Ensure the sealing devices are intact to prevent dust or moisture from entering the interior.

5. Conclusion

Conveyor rollers are crucial components in the operation of conveying equipment, and their quality and performance directly determine the stability and reliability of the conveyor system. When selecting rollers, it is important to consider the working conditions, conveyor belt specifications, and material characteristics to ensure efficient application in production.

If you have additional needs or require customized services, please contact us. We will provide professional solutions for you!

Performance and application of conveyor roller