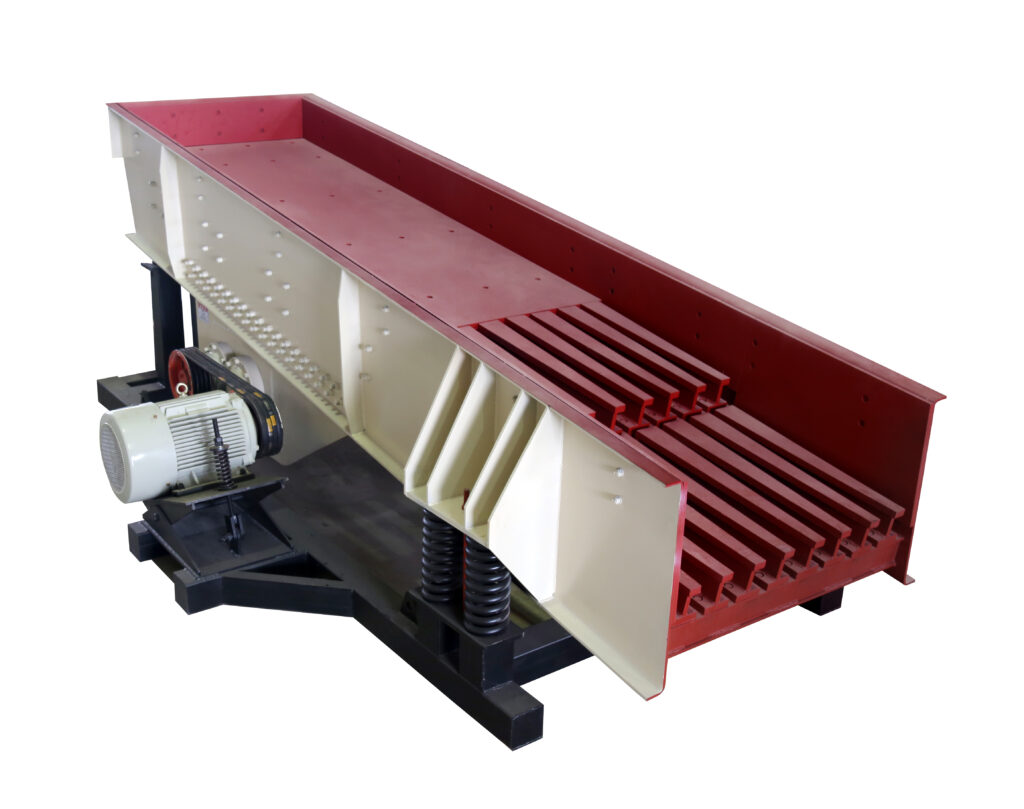

Idlers: An Essential Component of Conveyor Systems

Idlers are an indispensable part of conveyor systems, and their importance cannot be overstated. They function like the heart of the conveyor, providing continuous power to the entire system. This article will provide a detailed yet simple introduction to the structure, function, classification, selection, and maintenance of idlers.

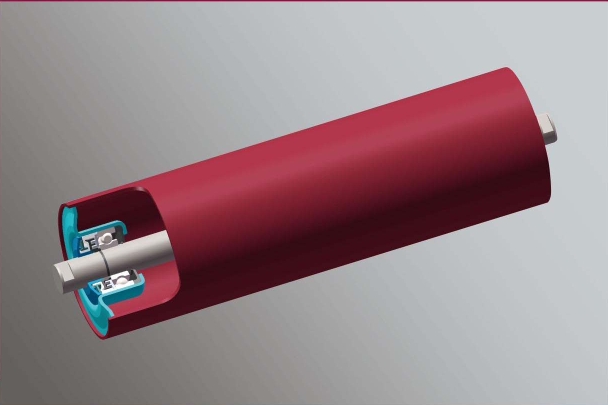

1. Introduction to Idlers

As the name suggests, idlers are rollers used to support the conveyor belt. By rolling, they reduce the friction between the conveyor belt and the idler, thus lowering the conveying resistance and extending the life of the conveyor belt. At the same time, idlers help ensure the smooth operation of the conveyor belt, preventing issues like belt misalignment.

2. Working Principle of Idlers

When materials are carried by the conveyor belt, the idlers support the weight of both the belt and the material by rolling. In this process, rolling friction is generated between the idler and the conveyor belt, which is much lower than sliding friction, effectively reducing the conveying resistance.

3. Classification of Idlers

Idlers can be classified in various ways, depending on different factors.

- By Structure: Parallel idlers, buffer idlers, spiral idlers, etc.

- By Material: Steel idlers, ceramic idlers, nylon idlers, etc.

- By Use: Standard idlers, high-temperature resistant idlers, corrosion-resistant idlers, etc.

4. Selection and Application of Idlers

The selection of idlers should be based on specific conveyor conditions, considering the following factors:

- Material Properties: The wear resistance, corrosiveness, temperature, etc. of the material.

- Conveying Capacity: The amount of material conveyed directly affects the load capacity of the idler.

- Conveying Speed: The speed of the conveyor influences the idler’s rotation speed.

- Environmental Conditions: The temperature, humidity, etc. of the working environment.

5. Maintenance and Care of Idlers

To ensure the proper functioning of idlers, regular inspections and maintenance are required. The main tasks include:

- Regular Inspections: Check for damage, deformation, looseness, or other issues with the idlers.

- Regular Lubrication: Lubricate the bearings of the idlers to ensure smooth rotation.

- Cleaning Debris: Remove any debris around the idlers to prevent interference with their normal operation.

Idlers are a crucial component of conveyor systems, and their performance directly affects the efficiency and lifespan of the entire system. Through this article, it is hoped that you have gained a deeper understanding of idlers. In practical applications, selecting the appropriate idlers and performing reasonable maintenance and care will ensure the stable operation of the conveyor system.