Mining Conveyor Supports are essential structural components used to support and fix the conveyor belt, rollers, and other related parts in a conveyor system. In industries such as mining, coal, and metallurgy, conveyors often operate under high intensity for extended periods, so the design and material selection of the supports are crucial to the stability and safety of the entire conveyor system.

Functions of Mining Conveyor Supports

- Support the Conveyor Belt: The primary function of the supports is to hold the conveyor belt in place and ensure its stability during operation.

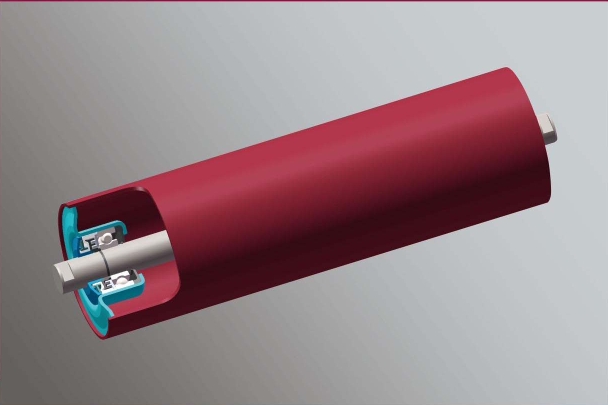

- Fix the Rollers: Supports are used to install and secure the rollers, ensuring that they operate smoothly and provide a stable path for the conveyor belt.

- Adjust the Belt Tension: In some cases, supports can be used to adjust the tension of the conveyor belt to ensure it does not become slack or overly tight during operation.

- Bear the Weight of Materials: Supports also bear the weight of materials being transported, especially in heavy-load conveyors, where the load-bearing capacity of the supports is crucial.

Features of Mining Conveyor Supports

- High Strength: Mining environments are often harsh, so the supports need to be strong and durable to withstand heavy loads and external pressures.

- Corrosion Resistance: Mining sites are frequently exposed to moisture, acid, and alkaline conditions, so the materials for the supports must have good corrosion resistance to ensure longevity.

- Impact Resistance: Since mining conveyors may encounter significant impacts and vibrations, supports must have impact resistance to prevent deformation or damage under high-impact forces.

- Adjustability: The design of the supports should allow for adjustments to optimize the working condition of the conveyor belt as needed.

Applications of Mining Conveyor Supports

- Mining Industry: The transportation of heavy materials such as ore and coal requires robust support structures. Mining conveyor supports provide stable support in these systems.

- Metallurgical Industry: The transportation of high-temperature and heavy-load materials in metallurgy also requires strong supports to stabilize the conveyor belt.

- Construction Industry: In construction, mining conveyor supports help efficiently and stably transport building materials.

- Coal Industry: The transportation of materials, especially coal, in coal mines requires large and strong conveyor support systems to ensure safe and efficient operation.

Selecting Mining Conveyor Supports

When selecting mining conveyor supports, the following factors should be considered:

- Working Environment: Choose materials with good corrosion resistance, high-temperature resistance, and other environmental adaptations according to the conditions at the mining site.

- Load Requirements: Supports should be chosen based on the weight of the conveyor belt and materials to ensure they can bear the corresponding load.

- Ease of Installation and Adjustment: Select supports that are easy to install and adjust to facilitate daily maintenance and operations.

- Material: Common materials for supports include steel and aluminum alloys. Choosing the appropriate material can improve the stability and durability of the supports.

Conclusion

Mining conveyor supports play a vital role in the overall conveyor system, providing stable support for the conveyor belt and ensuring the efficient and safe operation of the system. Selecting the right supports not only enhances the overall performance of the conveyor system but also effectively extends the service life of the equipment, reduces failure rates, and boosts productivity.