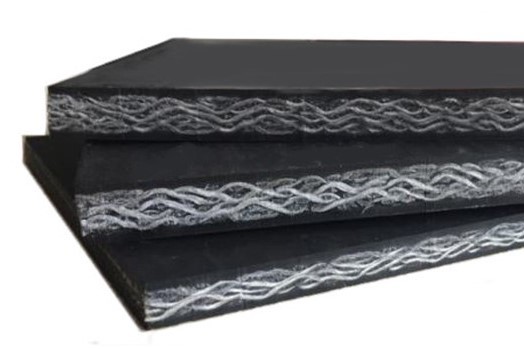

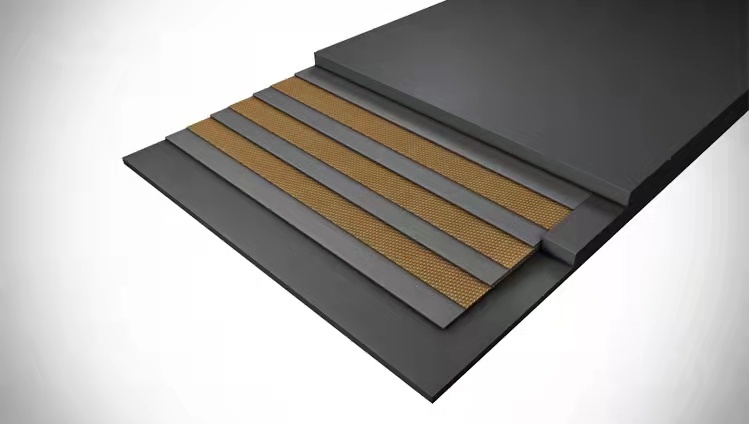

The overall core flame-retardant conveyor belt (PVC-PVG) is mainly used in coal mines. The features of this belt include: the body does not delaminate, small elongation, impact resistance, and tear resistance. Depending on the construction, it can be divided into PVC type (plastic surface) and PVG type (rubber surface added on PVC), both of which are overall core flame-retardant belts, and they comply with the MT914-2002 standard.

The overall core flame-retardant conveyor belt (PVC-PVG) is mainly used in coal mines. The features of this belt include: the body does not delaminate, small elongation, impact resistance, and tear resistance. Depending on the construction, it can be divided into PVC type (plastic surface) and PVG type (rubber surface added on PVC), both of which are overall core flame-retardant belts, and they comply with the MT914-2002 standard.

(1) PVC flame-retardant conveyor belts are suitable for transporting materials under dry conditions with a slope of less than 16 degrees.

(2) PVG flame-retardant conveyor belts are suitable for transporting wet materials with a slope of less than 20 degrees.

1. Model N/mm (Tensile Strength):

| Grade | Grade 4 | Grade 5 | Grade 6 | Grade 7 | Grade 8 | Grade 9 | Grade 10 |

| Model | 680s | 800s | 1000s | 1250s | 1400s | 1600s | 1800s |

2. Flame Retardant Performance:

(1) Drum Abrasion: The surface temperature of the drum should not exceed 325℃.

(2) Flame Test: The average flame-out time for the full thickness specimen under the flame test should not exceed 3.0 seconds, and for the covering layer, it should not exceed 5.0 seconds.

(3) Propane Combustion: The undamaged length should be greater than 250mm.

3. Surface Resistance Value:

The average value for both the upper and lower surfaces should not exceed 3.0×10^8Ω.

4. Performance:

This conveyor belt has passed flame retardant and static electricity tests and obtained the certification coal safety mark and customer recognition.

5. Mechanical Performance:

The mechanical performance is excellent, offering users a longer service life and cost-effective installation and usage.

Service life: The service life of the belt body is determined by factors such as the longitudinal and transverse filaments and the dense belt core woven from cotton-spun fibers. It is impregnated with a specially formulated PVC material that achieves a high adhesive strength between the core and the cover rubber, which makes the belt body impact-resistant, tear-resistant, and wear-resistant.

This product has excellent wear resistance, antistatic, waterproof, flame-retardant, and high-strength performance. Compared to other flame-retardant conveyor belts, it offers lower costs and more affordable prices. It is one of the most commonly used flame-retardant conveyor belt types, particularly suitable for inclined transport areas like coal mines.

6. Product Structure:

The product uses an overall core as the skeleton material, which is impregnated and coated with PVC material with antistatic and flame-retardant properties.

7. Joint Performance:

Depending on the belt strength and core structure, mechanical fasteners can be used, with the joint strength reaching 50%-100% of the belt body strength; with vulcanized joints, the strength can reach 60%-100% of the belt strength. Multiple joint types can meet customer needs and ensure the safe and efficient operation of the system.

| Average Surface Resistance Value | ≤3×10^8Ω |

| Drum Abrasion Performance | Maximum allowed temperature ≤325℃, and no flame or non-flame combustion phenomena should occur. |

| Alcohol Torch Flame Test | Average value ≤3 seconds (with cover), single value ≤10 seconds (with cover), average value ≤5 seconds (without cover), single value ≤15 seconds (without cover) |

| Propane Tunnel Combustion Performance | Undamaged length segment >250mm |

| High-Energy Tunnel Propane Combustion Test | Undamaged length segment >2250 |

| Product Specifications | Tensile Strength (N/mm) | Tensile Elongation (%) | Tear Strength (N) ≥ | ||

| Longitudinal ≥ | Transversal ≥ | Longitudinal ≥ | Transversal ≥ | ||

| 680S | 680 | 265 | 15 | 18 | 1090 |

| 800S | 800 | 280 | 15 | 18 | 1180 |

| 1000S | 1000 | 300 | 15 | 18 | 1180 |